{Satisfying tough specifications of hypothermic deployments involves dedicated valve solution. The company’s arctic 3-way circular device remedies are manufactured to provide unwavering effectiveness even at extremely low temperatures, typically below -150°C. These systems offer outstanding circulation management in refined gases such as nitrogen, oxygen, and argon, frequently deployed in realms like LNG, laboratory equipment, and biomedical facilities. We prioritize hardy construction, including frictionless shutting items and precise forming, to certify hermetic activity. Evaluate the pros of advancing your freezing system with our cutting-edge 3-way ball piece remedies.

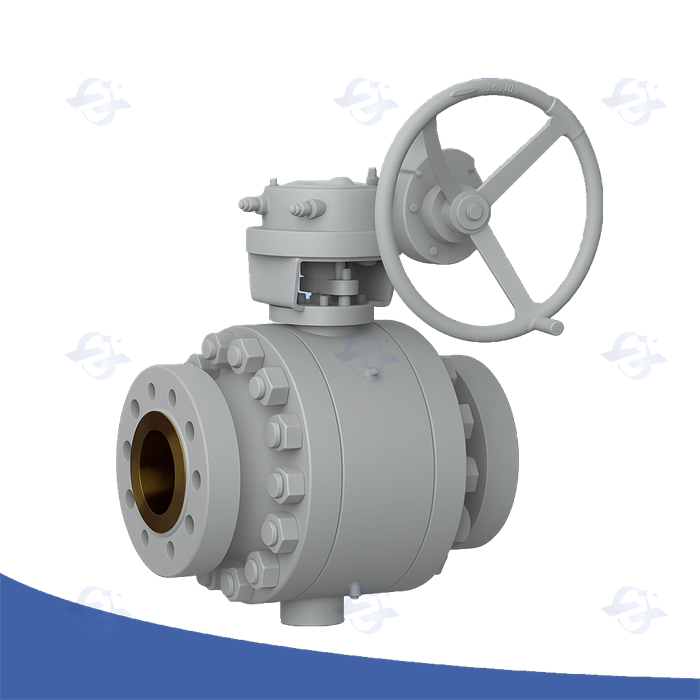

Superior Double Block and Bleed Ball Valves

In terms of key systems, particularly where spillage is taboo, top-tier double block and bleed ball valves offer unequalled assurance. This innovative design incorporates two discrete rotary valve seals, further a bleed outlet, allowing for substantiation of the full shut-off and detection of any expected seepage. Regularly employed in oil and gas procedures, refining fabrication, and arctic locales, these assemblies dramatically augment operational assurance and reduce the chance of ecological impact.

Three-Directional Chilling Globular Instrument Blueprint

The development of three-way cold spherical tap presents a distinct engineering hurdle. These taps are frequently employed in key industrial implementations where intense climatic states must be maintained. Key factors include compound option, in particular regarding susceptibility at small coldness, and the requirement for airtight fastening to deter leakage of chilling materials. Advanced examination styles and thorough assembling procedures are fundamental to confirm consistent output and persistence under such challenging utilizing circumstances.

Arctic Control Device Capability in Industrial Applications

That demanding criteria of subzero applications, such as subzero natural energy handling and frozen nitrogen storage, necessitate reliable monitor methods. Integral block purge components provide a particularly robust and effective system to achieving zero-leak closure while facilitating regular maintenance. Their design embeds a primary assembly with a small opening path, allowing managed pressure discharge during stopping and reopening. This inherent aspect minimizes lingering item entrapment, thereby ensuring outstanding defense and efficiency even under the most harsh employing environments. Furthermore, the capability to oversight drain movement provides valuable analytical information for activity maximization.

Attaining 3-Way Circular Valve Tightness in Demanding High-Pressure Contexts

Accomplishing consistent closure performance with 3-way round valves becomes particularly important when operating within intense pressure conditions. The design requires to account for significant burdens and potential seepage pathways. Specialized elements, often including cutting-edge metals like anti-corrosive steel or exotic alloys, are necessary to bear the extreme conditions. Furthermore, innovative contact geometries and meticulous manufacturing processes are mandatory to minimize compression and guarantee a leak-proof union even under fluctuating burden cycles. Regular monitoring and preemptive overhaul programs are furthermore vital for endurance and sustained operational reliability.

Frostbitten Ball Valve Leakage Prevention Strategies

Suppressing "spillage" from cryogenic "cryo valves" demands a multifaceted "strategy". Initial "construction" considerations are paramount; material "decision" must account for extreme "chills" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "compound", meticulous "creation" processes – including stringent weld "inspections" and non-destructive "testing" – are vital to ensure structural integrity and eliminate voids that could become "escape routes". A "essential" component is proper "arrangement"; thermal "condensation" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "maintenance" – including periodic "review" for signs of wear and "mending" of any identified issues – is indispensable for maintaining a reliable, leak-tight "joint”. Ultimately, a robust "program" incorporating these elements is necessary to ensure the safe and efficient "performance" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shrinking", safety "menaces", and costly "pause”.

Double Seal and Vent Component Inspection Procedures

For certifying the integrity and safety of critical piping frameworks, rigorous twin clamp and drain mechanism check protocols are essential. These tests, often mandated by regulatory bodies and industry best standards, typically involve simulating simultaneous closure of two isolation apparatuses while simultaneously ensuring the discharge valve remains functional and correctly discharges any trapped fluid. A common method is to utilize a pressure assessment where the system is pressurized to its maximum working pressure, and the seepage rate around the closed devices is meticulously measured. The bleed system's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of analysis results, including any variations observed, is indispensable for maintaining a reliable workflow.

Realizing Whole Block Purge Tool Operation

With the purpose to adequately handle load frameworks, a meticulous knowledge of integral block release component operation is totally essential. These dedicated sections mostly perform to successfully discharge redundant power from a network during particular engaged periods. A common setup includes a sealed portion combined to the key load source, enabling the controlled letting out in case essential. The innate plan curtails the possibility of pressure overload, preserving both the machinery and the nearby environment. Regular supervision and preservation are mandatory to secure maximal operation.

Identifying the Correct 3-Way Ball Valve for Cryogenic Fluids

Choosing a apt 3-tri-ball mechanism for cryogenic implementations demands careful assessment of several critical features. The extremely low temperatures inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present atypical challenges. Material election is paramount; only materials with proven agreement and ductility at these temperatures, such as oxidation-resistant steel grades like 304L or 316L, or specialized pure alloys, should be evaluated. Furthermore, the assembly's sealing proficiency is vital to prevent escapes, requiring unique stem sealing formations and low-temperature lubricants. Finally, pressure measures and actuation means, taking into account potential pressure surges, must be rigorously matched to the system's requirements. Neglecting these factors can lead to critical failure and safety risks.

Freezing Circular Valve Constituent Suitability Handbook

Opting for the appropriate compound for cryogenic ball valves is paramount, given the acute temperatures involved. This directory highlights common components and their functionality when exposed to cryogenic fluids such as fluid nitrogen, solution helium, and oxygen. Stainless steels, particularly sorts 304 and 316, often demonstrate adequate hardness and rust resistance, though martensitic metals require careful consideration regarding embrittlement. Aluminum alloys can be suitable for certain applications, however, their workability and endurance to specific chemicals needs detailed evaluation. Copper alloys, while offering some plus points, may exhibit subdued efficiency at these low temperatures. Consultation with fabricators and comprehensive testing is essential to guarantee permanence and dependability in cryogenic applications.

Maximizing Double Block and Bleed Arrangement Effectiveness

Achieving optimal capability in double shutoff and vent applications hinges on a multifaceted plan. Careful review of module selection is vital, with a focus on constituent correspondence and compression specification. Regular assessment of vent conduits for congestion is essential, often obliging the use of advanced diagnostic instruments. Furthermore, protocol improvement—including inspection of transfer rates and strain contrast—can dramatically amplify overall installation firmness and guarding. Finally, congruence to fabricator directives and the enforcement of a complete upkeep program are imperative for long-term trustworthiness and continuity.

best cryogenic ball valves

best cryogenic ball valves