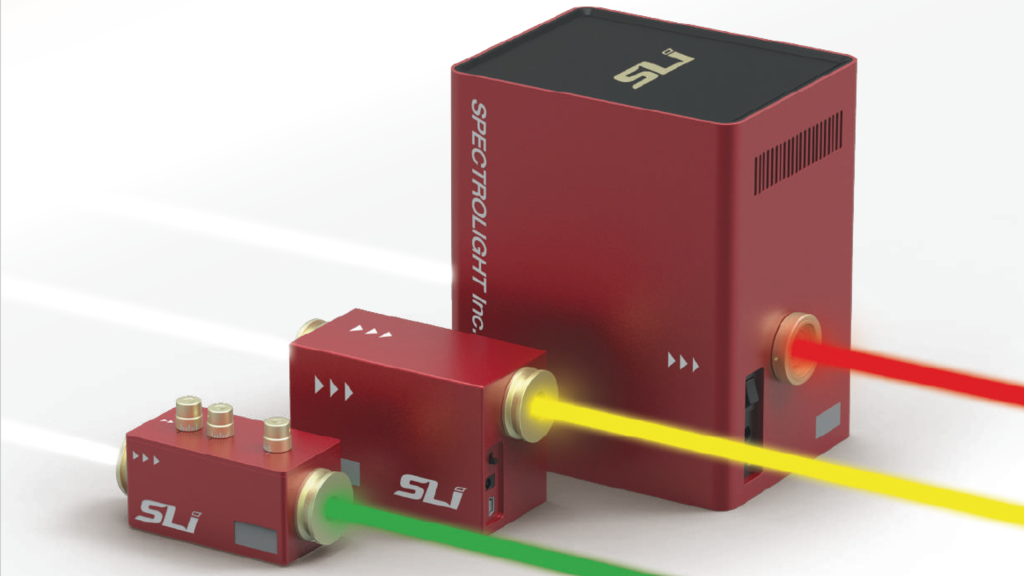

Advancing industrial inspection with Picanet interface 監控繼電器 together with CAN XL technology

The advancing sophistication of advanced mechanized systems systems obligates robust surveillance and diagnostic instruments. Utilizing Picanet, a state-of-the-art communication protocol configured principally for mechanical realms, integrated with the boosted capabilities of CAN XL, yields a forceful solution for instantaneous device insight. CAN XL's enhanced transfer rates and extension assist seamless integration with Picanet networks, permitting efficient broadcasting of indispensable operational data. This article considers the merits of introducing Picanet control with CAN XL in manufacturing automation applications, underlining its impact on system stability.

- Also, this method assists forward-looking maintenance by supplying valuable awareness into system health and possible issues before they heighten.

- The elasticity of Picanet, in concert with CAN XL's extended capabilities, makes it an preferred solution for a comprehensive spectrum of automated systems applications.

Connecting Vuzix Smart Glasses for Remote Watch

Vuzix smart glasses are progressively growing a versatile apparatus in the realm of remote surveillance. These novel devices enable staff to observe live recordings from assorted locations, delivering a hands-free and interactive perspective. With their featherweight design and straightforward interface, Vuzix smart glasses facilitate productive remote monitoring endeavors.

- Furthermore, Vuzix smart glasses can be combined with existing surveillance systems, empowering for a seamless workflow.

- These integrations increases situational awareness by furnishing attendants with a thorough understanding of the surveyed environment.

The multi-functionality of Vuzix smart glasses befits them for a varied selection of implementations, including inspective duties, site assessments, and emergency response. As tech continues to develop, we can predict even advanced uses for Vuzix smart glasses in the domain of remote surveillance.

Building and Applying CAN Relay Control Networks

This review examines the framework and installation of a durable CAN-based relay control system. Employing the characteristics of the Controller Area Network (CAN), this system enables on-the-fly communication between a main controller and remote relay modules. The design incorporates cutting-edge tactics to ensure faultless control of the relays, optimizing system performance. Besides, this platform exemplifies the strengths of CAN technology in technological applications, where dependable control is paramount.

- This system contains a central controller, relay modules, and a CAN bus.

- CAN offers a multiplexed communication channel for the regulator to manage relay states.

- The software toolkit is designed to coordinate interaction between the controller and relay modules.

Execution of this system necessitates circuitry design, software development, and platform integration. Exhaustive testing is accomplished to validate the functionality and robustness of the system under assorted operating settings.

Supervising Relay Status On-the-Fly using PCAN Interfaces

Leveraging PCAN interfaces grants a stable solution for real-time monitoring of relay status within industrial control and control systems. These rapid communication interfaces support seamless data transfer between PLCs, microcontrollers, and host computers, facilitating constant observation of relay activation states. The ability to observe relay behavior in real time delivers invaluable insights into system performance, permitting rapid response to potential issues or malfunctions.

- PCAN interfaces deliver a reliable platform for real-time data acquisition from relays.

- Real-time monitoring of relay status facilitates efficient troubleshooting and maintenance.

- Moreover, PCAN interfaces empower high data transfer rates, offering accurate and timely relay status updates.

Improved Visualization Techniques for CAN Bus with Vuzix XR

Revealing the potential of real-time automotive diagnostics and analysis has become markedly crucial in today's connected world. Vuzix XR smart glasses grant an innovative platform for visualizing sophisticated CAN bus data, giving engineers and technicians a hands-free, immersive perception into vehicle systems. Through advanced illustration techniques, critical parameters such as speed, temperature, and fuel levels are presented in a lucid and concise manner, overlaid onto the user's eye path. This groundbreaking strategy enhances technicians to speedily identify anomalies, diagnose issues accurately, and ultimately streamline maintenance procedures.

- The combination of Vuzix XR's augmented reality capabilities with comprehensive CAN bus data incorporation provides a transformative solution for the automotive industry.

- By leveraging on-the-spot data streams, engineers can monitor vehicle performance in fine detail, gaining valuable insights that drives innovation and efficiency.

- The hands-free nature of Vuzix XR supports technicians to competently work on vehicles while simultaneously accessing critical information, increasing productivity and safety.

Remote Relay Access and Control via CAN XL

CAN XL's extended data frame length grants a powerful platform for long-range accessing and controlling relays. This article reviews the implementation of utilizing CAN XL for relay management, emphasizing its favorable aspects. By taking advantage of the CAN XL system, users can conveniently monitor and manipulate relay states from a remote location. This approach grants augmented system elasticity and lessens the need for physical interferences with relays.

- Additionally, CAN XL's inherent reliability ensures reliable communication even in harsh environments.

- As a result, domains such as automobile can employ CAN XL to build more smart and automatic systems.

Proactive Relay Service Using CAN XL and AI Technology

In the growing automated world of industrial operations, confirming the reliability and uptime of paramount equipment is imperative. Relay systems, essential components in many automation structures, are prone to wear and tear over time, perchance leading to failures and costly downtime. To lessen these risks, implementing predictive maintenance strategies has become critical. CAN XL, a high-speed, robust communication protocol, furnishes a suitable platform for gathering real-time data from relay systems. By utilizing the capabilities of Machine Learning algorithms, this data can be evaluated to spot patterns and predict potential failures before they happen.

- Machine Learning models can be trained on historical data from relay systems to construct benchmarks for normal operation.

- Real-time data collected via CAN XL can then be compared against these baselines, granting the detection of deviations that may indicate impending failures.

- By processing this information, predictive maintenance systems can produce alerts to technicians, supporting timely intervention and curtailing costly downtime.

Picanet and CAN XL for Advanced Smart City Oversight

Current networked urban environments are rapidly reliant on robust and powerful infrastructure monitoring systems. To accommodate this increasing need, innovative technologies like Picanet and CAN XL are arising as game-changing solutions. Picanet's wireless architecture supports seamless data transfer across a wide range, while CAN XL offers augmented bandwidth and longer transmission stretches. By interlinking these technologies, cities can achieve real-time management of critical infrastructure assets such as traffic flow, energy grids, and environmental sensors. This cohesive approach uplifts smarter decision-making, streamlines resource allocation, and ultimately elevates the quality of life of urban residents.

Advanced AR Relay Inspections Using Vuzix Devices

Vuzix's advanced augmented reality (AR) equipment present a pioneering approach to industrial relay inspections. By overlaying synthetic graphics onto the material world, technicians can reliably assess relay modules for wear and tear, discovering potential anomalies. This sensor-based inspection method enhances technician performance, reducing downtime and optimizing overall wellbeing on the job site.

- Furthermore, Vuzix AR platforms allow real-time communication between technicians and experts, building accelerated diagnosis.

- As a result, Vuzix AR optimizes the relay inspection process, producing a more dependable and cost-effective option.

Optimizing Relay Functionality through Live CAN Data Evaluation

Reaching optimal element performance within complicated systems often relies on comprehensive monitoring of real-time data. Controller Area Network (CAN) provides a strong platform for collecting this critical information, empowering in-depth insights into relay behavior and system condition. By applying real-time CAN data assessment, engineers can detect potential issues, improve relay settings for superior performance, and ultimately improve the overall reliability and performance of the system.

- Real-time CAN data analysis grants a valuable tool for identifying anomalies in relay behavior.

- Adopting real-time monitoring systems can significantly improve system analysis.

- By analyzing CAN data, engineers can determine relay performance metrics such as cycle duration.

Safe Transmission Protocols in Relay Networks

Relay control networks count on secure communication protocols to safeguard the integrity and confidentiality of transmitted data. These protocols facilitate reliable message passing between relay nodes and central controllers, defending against unauthorized access, interference, and eavesdropping. Integrating robust protocols such as SSH is necessary for maintaining the security and reliability of these networks. This secures efficient and safe operation in critical applications ranging from industrial automation to smart grids.